Search This Supplers Products:plastic injection moldplastic injection partsRapid prototype

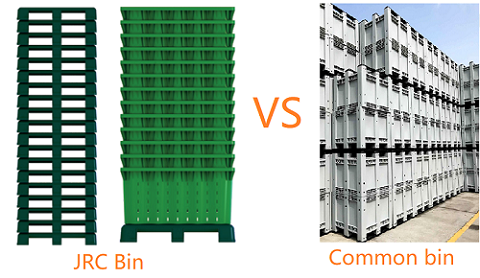

Warehouse Plastic Stackable Storage Bins

- group name

- JRC Bin

- Min Order

- 1 set

- brand name

- LONGXIANG

- model

- JRC bin 1

- Nearest port for product export

- Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Cash

- update time

- Sun, 19 May 2019 22:47:38 GMT

Paramtents

Material Food grade PP

Size 1165x1090x780mm

Volume 780L

Max load capacity 500kgs

Operating Temperature Range -30 to 50 ℃

Unit weight--2-way vented 38kgs

Unit weight--2-way non-vented 40kgs

Packging & Delivery

-

Min Order1 set

Briefing

Lock & Save Produce Bin and Pallet design gives you maximum storage and stacking capability

Detailed

What is Lock & Save Produce Bin?

Australia’s most versatile storage and transport solution for agricultural, meat and poultry producers, setting a new standard in sustainable, efficient and hygienic reusable bulk bins.

Made from high quality food-grade plastics and both fast and easy to assemble, the Lock & Save Produce Bin? is a tough, light-weight storage bin using a patented Lock and Unlock system.

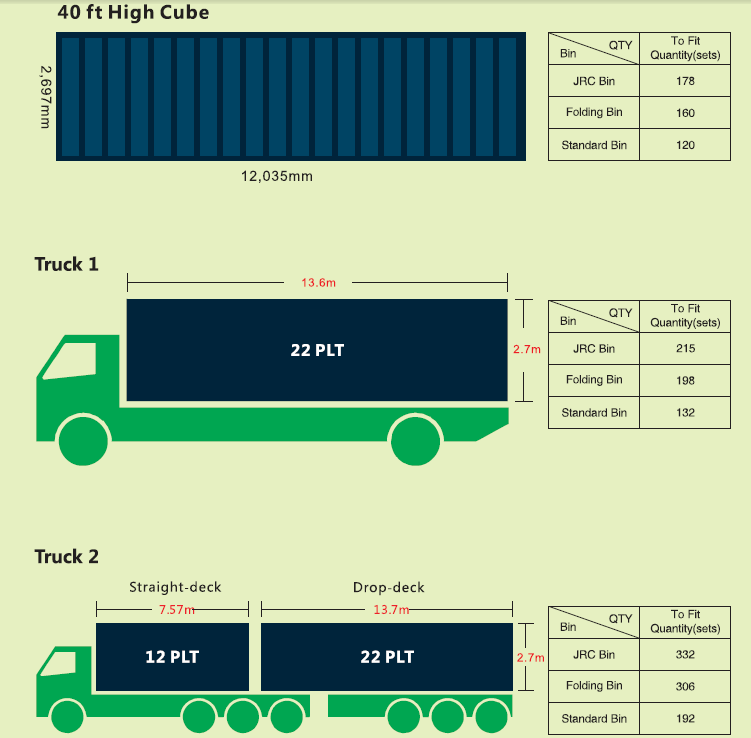

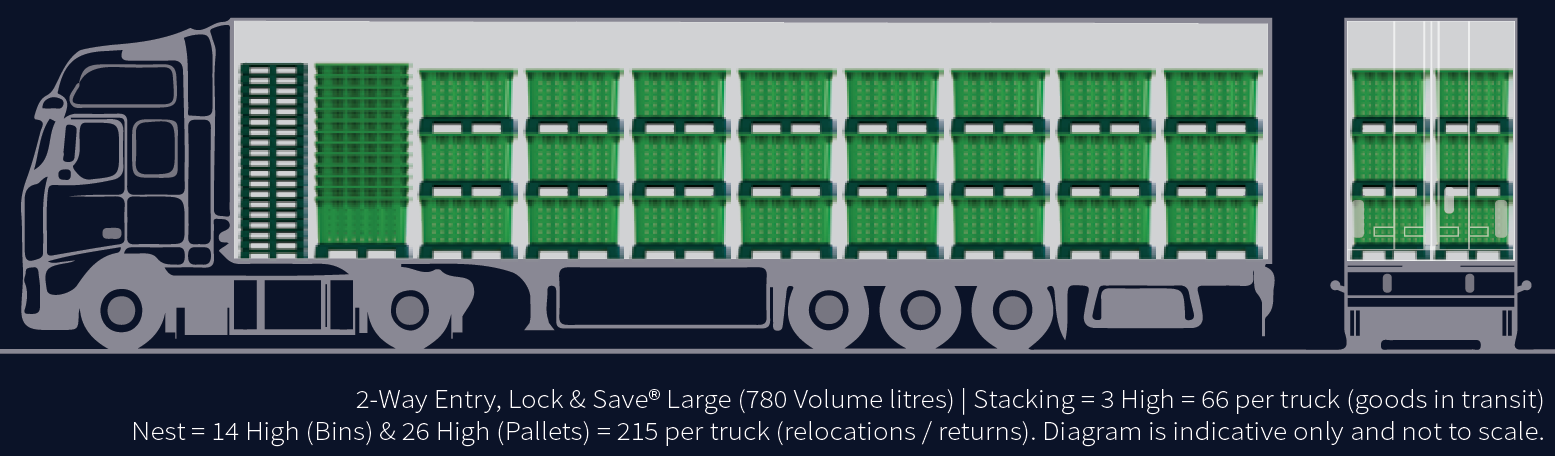

Producers can safely combine a nesting bin and pallet for food storage, capable of stacking up to ten bins high. Our patented Unlock system separates the nesting bin and pallet for maximised storage capability, providing a stacking height of 26 nesting bins and 38 pallets for our Large 780 L Nesting Bins.

The Lock & Save Produce Bin patented corrugated nesting design and chamfered venting holes significantly lessens food bruising and improves hygiene standards by reducing exposure to bacteria and fungal growths.

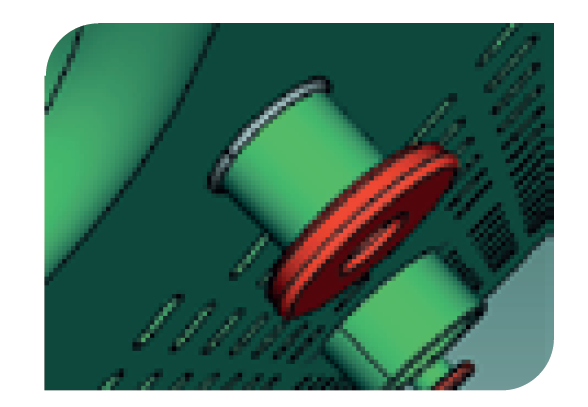

Our unique Lock and Unlock technology also maximizes workforce deficiencies and employee safety, utilizing unique patented locking mechanism that requires one person operation when connecting and disconnecting the nesting bin from the pallet.

Importantly, our bins are compatible with existing plastic food bins in the market.

What does Longxiang do?

Longxiang Group Limited was established in Dongguan city in 1998. After over 18 years of hard work, Longxiang has grown to be one of the highest reputable mould maker in China with 120 employees 5000 sq.meter working shop. We offer one-stop service from product design, rapid prototype, mold making, injection service.

JRC BIN is an important project in Longxiang. JRC bin design is from Australia, it takes two year to develop.

JRC Bin Feature

1. Up to 30% lighter than standard reusable bins

2. Compatible stacking with existing plastic fruit bins in the market

3. More durable, using high quality food grade plastics

4. Vented and Non-Vented nesting bins

5. No liner bag required for meat and poultry storage, reducing packaging costs

6. Better hygiene control, easy to clean and impervious to moisture

7. Unique patented corrugated design and increased ventilation reduces product damage, and improves pack out rate

8. Patented interlocking ‘Lock & Unlock’ technology allows for one person operation

9. Storage nesting to 38 High pallets and 26 High Nesting Bins using Large 780 L solution

10. Bin and Pallet stacking capability significantly reduces transport and relocation costs, allowing up to 215 nested bins/pallets per truck

Advantage 1:

Comparing with compatible bins, our bins & pallet are separated could stack, save space and freight charge.

Advantage 2 :

Corrugated and chamfered design reduces food damage and is easy to clean.

Advantage 3:

Our unique Lock and Unlock technology also maximises workforce eficiencies and employee safety, utilising unique patented locking mechanism that requires one person operation when connecting and disconnecting the nesting bin from the pallet.

Application